The term digital twin is being used frequently these days. However, if you start looking for a clear definition you will soon notice the term is being used with different meanings.

Twenty years ago, the concept of a digital twin was introduced by engineers, at that time as “a digital prototype”, a digital 3D design drawing. Until then, product design was mostly based on physical prototypes in wood or metal. In this blog, we take a closer look at what the digital twin means today and what it can apply to.

Digital simulation

Today, Gartner defines in its IT glossary digital twin as “a digital representation of a real-world entity or system. The implementation of a digital twin is an encapsulated software object or model that mirrors a unique physical object, process, organization, person or other abstraction.”

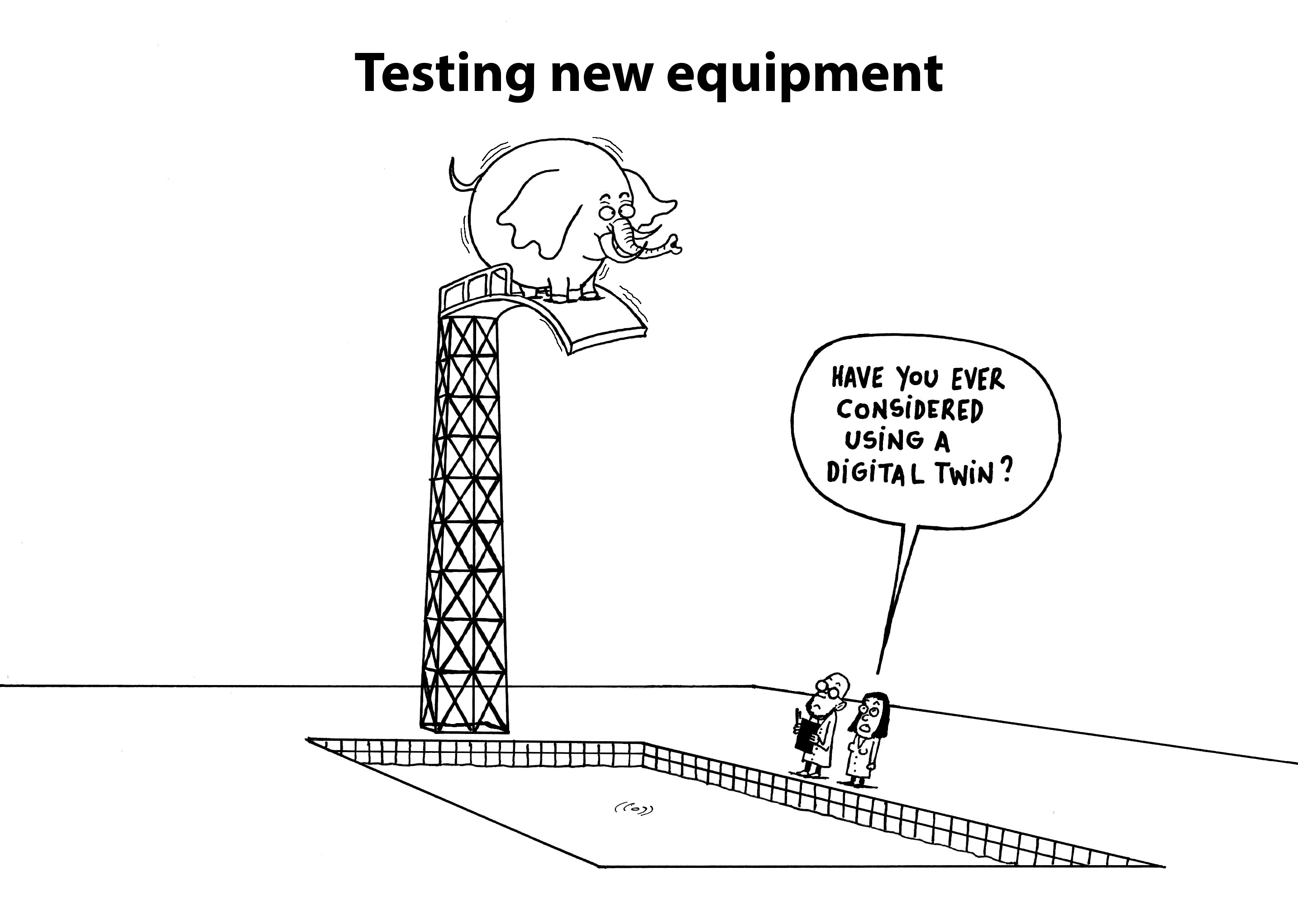

Simply stated, a digital twin is a piece of software that simulates something from the real world. It is useful because it allows the user to simulate a situation without having to do something in the real world. That is still a broad definition, therefore the use of the term depends very much on the context.

Some examples

For instance for the traffic engineer, responsible for the traffic in a big city, the digital twin of the city will be software that simulates how the traffic will be affected by planned roadworks. It will allow the user to compare the impact of different scenarios for roadwork.

The manager of a production plant may see a digital twin as a software simulation of his plant, allowing him to simulate the effect of making changes to the production lines on the plant capacity and processing times. No need to explain the benefit for the manager being able to predict the impact instead of having to test in real life.

A maintenance manager may use a digital twin to simulate the impact of time and usage of the production equipment to predict when maintenance will be required.

Digital twin and AI

There are digital twins purely based on a theoretical model to do simulations, but nowadays AI models are also involved. AI models use data from the past to predict the future of systems that are not easy to model. This opens a lot of opportunities, given there is enough data available to train the model initially. Digital twins will often have a connection to their twin in the real world. In practice, sensors or smart devices (IoT) will provide an almost continuous flow of data from the real world to the digital twin. That data provides a good view on the current state of the real world twin, and may also be used to improve the simulation capabilities of the digital twin.

From the above, it is clear the term “digital twin” can cover very different meanings depending on the context. The basic common functionality is however, the capability to simulate a system or situation of the real world in a purely digital way.

Want to read more about this topic? In the blog article below, you will discover how we build an offshore wind planning optimization tool where we also set up a digital twin.